So I have decided to document my brewery build for family and friends who are interested in seeing the progress and how it works.

What is HERMS?

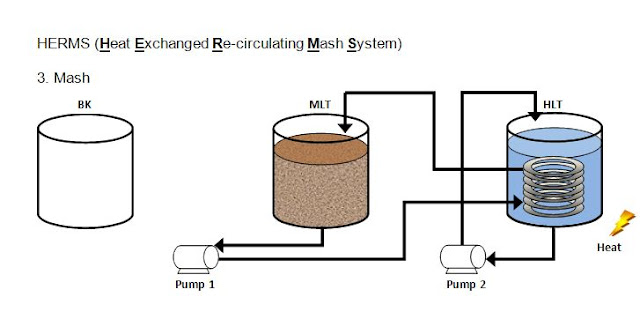

First off, my brewery will be what is know as a HERMS setup, or more specifically, an E-HERMS setup. HERMS stands for Heat Exchanged Re-circulating Mash System. The E means that it is an electric system. I will be using 5500w water heater elements as a heat source.

One of the most important parts of brewing is the mash. The mash is when you take your crushed grain and let it sit in hot water for an hour or an hour and a half and the enzymes in the grain convert all the starch to sugar. This sugar will eventually be consumed by yeast and converted to ethyl alcohol and CO2. The problem is that it is hard to keep the mash at the right temperature during the hour unless you can apply heat. Many people use a cooler as a mash tun and cannot directly apply flame heat. A HERMS setup will allow you to move liquid out of the mash tun to a heat exchanger where it will be pulled up the the proper temperature and then put back into the mash.

Lets start by getting used to some of the basic terminology. My brewery will be a single tier system. That means that all the kettles will be on the same level. Some brewers use 2 or 3 tier setups. The advantage of this is that you can use gravity to move liquid from one vessel to another. The downside is that they can be fairly tall and you have to hike the liquid to the top to start with. A single tier has all the vessels within easy access. The downside is it is not easy to get liquid from one vessel to the next.... unless you use pumps.

There are 4 main vessels in standard brewery setup but most brewers use one vessel for two purposes (Mashing and Lautering) so that leaves 3. They are the Boil Kettle or (BK) the Mash/Lauter Tun (MLT) and the Hot Liquor Tank (HLT).

Lets examine how this process will work.

The HLT is filled with water. There is a stainless steel coil in here that will be used as a heat exchanger later. We turn on the heater element and the water is heated until the proper temperature is reached. The temperature is calculated so that when the water is mixed with the grain in the mash, it will come out the the right temperature for the mash. Water is circulated through the vessel via a pump to equalize the temperature.

The MLT is filled with the crushed grain. The proper amount of water is transferred from the HLT to the MLT by pump. The water is mixed very will with the grain making sure to break up any grain balls that form. The process is known as 'Doughing in'.

During the mash, water in the HLT is kept at the proper temperature in the HLT by use of a PID. A proportional-integral-derivative controller (PID controller) is a generic control loop feedback controller. It will monitor the temperature and apply heat to keep it at a set temperature. The water is circulated in the HLT to keep the temperature constant throughout the vessel. The liquid in the mash is pumped out of the MLT and through the stainless coil in the hot water in the HLT and then back into the mash. This will then maintain the temperature of the mash at the temperature of the HLT.

After all the starch has been converted to sugars in the mash we need to rinse all these sugars and collect the sweet liquid known as wort. This process is know as sparging or lautering. We pump out water that is about 170 degrees F from the HLT back through the coil to get out all the sweet wort into the MLT. At the same time we pump sweet wort from the mash to the BK. We try to do this at a fairly slow rate so the water can filter through the mash and rinse out the sugars. We also try to match the flow rates between the two vessels so we maintain about a 2 or 3 inch cover on the grain bed. We do this until we have collected the volume we need for the boil.

Heat is applied by a water heater element in the boil kettle and the wort is boiled for one to one and a half hours. During this time hops are usually added. Hop oils are isomerized and proteins are coagulated and 'bad' compounds are driven off during the boil.

After the boil we need to cool the wort as quickly as possible. We want to get the yeast pitched as soon as we can so they can start converting the sugars and get a hold before any bacteria can. During the last 15 minutes of the boil we place a copper coil used for cooling into the boiling wort to sanitize it. After the boil, we run cold water through the coil that is in the wort and it will pull the heat out of the wort with it. At the same time we circulate the wort through the pump back into the kettle and around the coils to help cool it.

We then drain the cooled wort out of the BK into the fermenter, apply some oxygen via an O2 tank or just mixing and then pitch the yeast.

Damn that was a lot of typing. Hopefully you got something out of that. I will be adding posts that have pictures and descriptions of what I have finished as I go. Stay tuned!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.